- Real-time monitoring with IPS touch screen display

- Support WiFi, USB, Ethernet connectivity for data transfer

- Built-in 720 HD camera to control over 3D printer

- Breakpoint printing function with specialized textbook

- Permanent levelling design printer with the smart cooling system

- Durable, shatterproof and Anti-UV cover protection design

- Ultra-quiet noise with less than 50dB

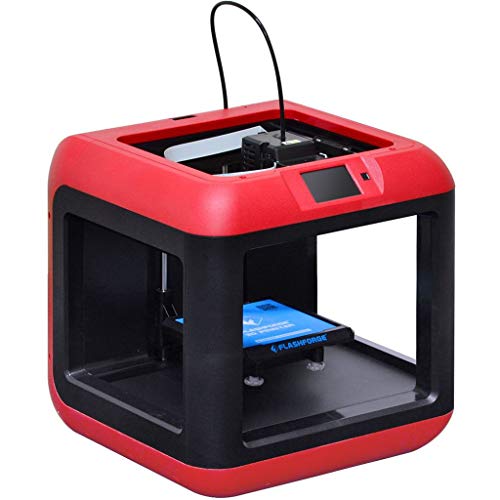

- Fue Filament Fabrication printing technology

- Built-in web user-interface for architecture printings

- Removable Magnetic Build surface for hassle-free cleaning

- Print from iOS, pc and android devices

- Print speed upto 150 mm/s and 0.1 mm print resolution

- Features air purification and power outage

- Prints nylon, carbon fibre and polycarbonate materials

- Smart-support with Auto-generation system

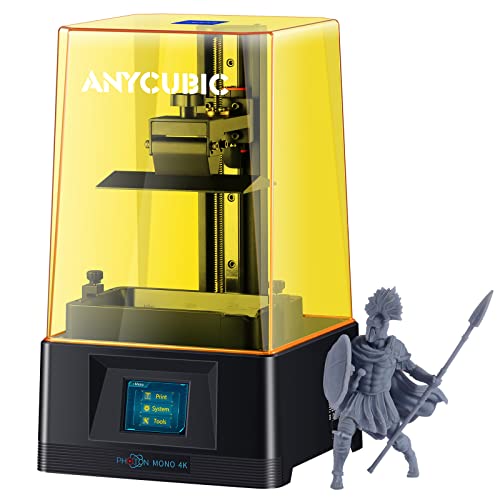

- LCD stereolithography printing technology

- Filament runout detection and touch screen interface

- Built-in camera for remote monitoring

- Automatic levelling and fast slicing software

- Wifi remote control system for large printings

- Air circulation system for odour free printing

- Self-developed slice software for fast 100M slicing files

- Unique industrial design with screw levelling for printing

- UV photocuring technology for 3D printing

- Round edge and fully enclosed nozzles

- Smartphone and WiFi connectivity for easy control

- Compatible with elastic, pearl, HIPS and TPU filaments

- Enhanced High heat resistant platform

- High-quality CNC materials for consistent printing performance

- 405nm photosensitive resin printing material

- Printing of PETG, PLA, PVA and wood filament materials

- Bowden style Titan Extruder with improved hotend design

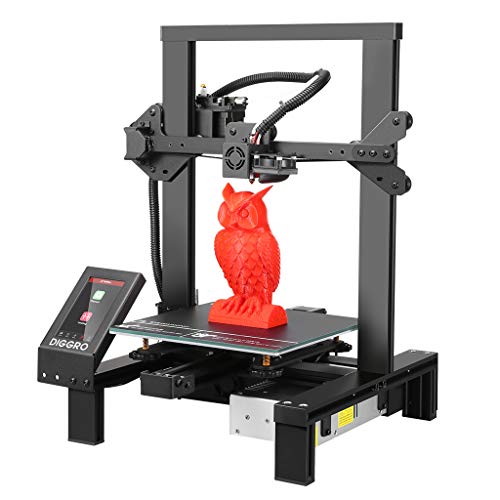

- FDM technology printer with easy DIY installation

- Great printing quality with a large volume

- Budget-friendly 3D printers for professional use

- An automatic temperature control system

- Z-axis dual linear resin with high precision

- Integrated tempered glass 3D printer

- Ensure hotbed leveling sensor

- Aluminium and sheet metal material

- Filament runout detection sensor

- Supports STL, OBJ and G-code file formats

- Single nozzle quantity with 0.4mm diameter

- Upgraded tempered glass surface for effortless printings

- Simple navigation through an easy touchscreen

- Printing speed up to 180mm/sec

- Levelling sensor with filament deduction technology

- Ideal for professionals and hobbyists discover

- 0.4 mm extruder diameter with a max temp of 260°C

- 3.5 inch IPS panel colour screen for easy and simple operations

- Colourful touch screen with a durable frame 3D printer

- Perfect for developing imagination to create unique designs

- Resume printing technology even after a power outage

- Space-conscious one-piece structure 3D printer

- Smooth and accurate 3D printer

- Support Windows, Mac, Linux operating system

- Fast heating and resuming temperature

- Access OBS and STL file format system

- Artistic and Creative printing prototype for STEM projects

- Fully open-source code to enhance innovative printings

- Self-developed intelligent operating system

- Automatically suspends printing when filaments run out

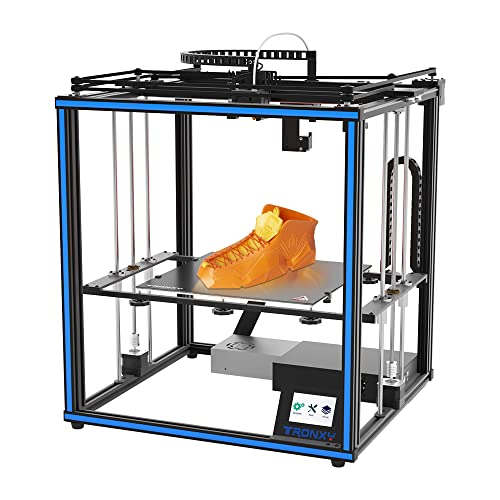

- Sturdy metal base and side filament holder for stability

- Filament runout detection sensor

- Metal extruder frame for better printing experience

- Prints on TPU, wood and copper-containing materials

- High precision guide rail with stable temperature

- Power failure detection technology with auto levelling sensor

Apply 10% Off Coupon Code "TRONXY3D2710"

- Fused deposition modelling technology

- Extrusion technology to reduce plugging risk

- Fast running speed with 72mhz frequency

- PLA, ABS, PETG, HIPS and wood filaments

- Durable and aluminium construction 3D printer

- Support 2GB micro SD card and store sliced GCode files

- FFC cabling and dual Z-axis system

- Rapid AC heated glass bed platform

- V-slot POM(polyoxymethylene) wheels for precision printing quality

- Best to create large and complex models

- Access Mac, Linux, Windows xp, and Vista operating systems

- Diagonal drawbar for a smooth printing

- Compact design with easy to follow instructions

- Prints PLA, ABS, HIPS and PETG materials

- Fully open-source code to improve innovative printings

- Ingenious and Imaginative printings ideal for STEM projects

- CE, FCC and PSE certified power adaptor

- Perfect for making toys, hero prototype

"Amazon, Amazon Prime, the Amazon logo and Amazon Prime logo are trademarks of Amazon.com, Inc. or its affiliates". AS AN AMAZON ASSOCIATE, WE EARN AFFILIATE COMMISSIONS FROM QUALIFYING PURCHASES.

Quick Summary

🏆 Best Overall: Phrozen Lite - Higher Printing Stability... | ⭐ Runner Up: QIDI Technology - Equipped With Camera M... | 💰 Also Great: NOVA3D Elfin- Smart Display And Wifi Pri...

What are the important things to consider when purchasing a 3D printer?

3D printers are slowly becoming popular due to their myriad uses. Thanks to technological advances in hardware production, owning a 3D printer nowadays has become more affordable. Now they have come in various models, with innovations, and you would have to find out what you want out of one before deciding what to buy.

How Does A 3D Printer Work?

Creating A 3D Model Via 3D Modeling Software

First, you'd have to create the concept via a 3D Model, and then you can either make yourself one or download it from a 3D repository. When making a model for yourself, you can use 3D modelling software, a 3D scanner, an app, or maybe a haptic device. As a beginner, you can acquire an open-source touch screen 3D printer software online for free, or If you need an industrial-grade type, you might have to pay for it.

Slicing

With slicing software, you can slice your model into hundreds or thousands of horizontal layers. Once the slicing is complete, the file is now fed into the 3D touch printer. It is then printed layer by layer.

Benefits Of Purchasing A 3D Printer

Family Activity

There is always the question of how you are going to spend family time with your kids. You might want something that is recreational and productive. We also want something educational but not boring. Well, the good news is 3D printing could be a very good way to go with encouraging your kids to be creative and practical as well.

Earn Money Through 3D Printing

You can begin by selling 3D printed objects as a part-time hustle. You can also do practical things like phone cases with special functions such as additional card slots (ID, credit card, etc.). Or, maybe you can spend time making toys and even sell them to your neighbours. Again, many things can come from this machine that still yet has to achieve its full potential as a viable and practical instrument looking into the future. There are some Best 3D printers for small businesses, like users can make use of it to earn money with ease.

What Do I Want To Print?

Art

One of the advantages of creating art through 3D printing is that you can make detailed 3D images that you have created using a computer. Your creation can come to life with the most intricate details and lifelike interpretation that would otherwise not be possible if merely done by hand.

Outdoor Objects

3D printing with its all-weather resin components may be very useful when it comes to decorating your lawn or maybe an ornamental garden. Your printer can build things that are resistant to natural elements, such as pots and medium-sized figurines that you can put on display out on the lawn.

Household Items

You can also come up with unique and cheap 3d printers designs for ordinary household products like cellphone holders, pen holders, medium-sized plastic bookcases, and even plastic cup holders. You can create plastic cobwebs or jack-o-lanterns, tree ornaments and even wreathes during Haloween. These are just a few of the things that you can make using a 3D printer.

What Should I Look For When Buying A 3D Printer?

SLA

Stereolithography printers make use of a process called photo-solidification. It is when chemical reaction forms layers and photos when focused at a certain point, solidifying the SLA resin. The SLA method is known to create exceptionally smooth and very fine details.

FDM

Fused Deposition Modeling Printer creates a heating filament that passes through a tube that exits into shapes along X, Y, and Z axes. These printers are known to produce horizontal lines along the sides and need some additional work to smooth out the lines. Most hobbyists use a Cartesian FDM Printer, as it offers more control and yields better results.

SLS

Selective Laser Sintering printers use a laser to focus on a point in a vat of powder. As the laser moves, powder solidifies right after it. SLS is ideal for industrial 3D printing.

DLP

Digital Light Processing and SLA are similar in that they both utilize polymerization to create each layer of the object. When light hits a point in the resin, it then solidifies into place. The output of DLP is known to be smooth and has a much better finish compared to FDM.

Printing Speed

With this 3D printer buying guide, the buyer must understand that printing in 3D doesn’t mean faster is better. It goes with printers that claim more than 150mm/s speed. Chances are, the quicker the printing, the lower the quality of the end product. You might want to take inventory of the objects that you plan to print/create. And, if you might be looking to print objects with more detail and intricate design, you would have to opt for the qidi 3D printer for personal purposes.

What about actual lead times for real-time printing? There is no exact measurement as to how many hours your printing will take. It can go as fast as 4 hours or as slow as 12 hours. It depends on how detailed and complex the output product is. The higher the resolution, the longer it takes to finish.

Printer Bed Size

Generally, you may say that you can go for a bigger size print bed just in case you might want to print larger objects. That in itself is fine. However, what is critical is whether the print bed is heated or not. You will need a stable foundation once the printer starts laying down the resin. The potential problem is if you don’t have a heated bed, the object might not sit steady. It could potentially result in a less than the accurate output of your design.

So, you can choose from either manually glueing the object to the bed by using an adhesive or using a heated bed to ensure that the object stays in place. Moreover, if you are using ABS filament, you will need a heated bed anyway. A PLA filament can do either heated or just an adhesive.

Which one should I choose from, Closed Or Open Frame 3D printer?

Somehow having a closed frame proved to be more advantageous than the open frame. For one thing, you would need to keep in mind the safety of the user. That includes other members of the family. Seemingly, the only advantage that the open frame offers is that you get full access and full view whenever something is being printed. There is risk of accidentally knocking over the whole thing or ruining the object that is being printed. Or even worse, accidental burning.

Printing Materials

- Standard Resin can come in grey and white colours. It is also best for prototypes and small gadgets but not strong enough for final products.

- Tough Resin They are mostly used professionally and for some engineering apps. Tough resin can hold in case of high impact usage.

- PLA Polylactic Acid is a plastic that is sourced from plants. It works for indoor use but degrades when exposed to the sun and water. Avoid using this material outdoors.

- Medical grade resin-It is safe for medical use and even in dental applications.

- PETG Polyethylene Terephthalate Glycol is used for food-safe objects.

- ABS Acrylonitrile Butadiene Styrene is very strong plastic. These types of 3D printers are suitable for outdoor objects like the garden or the lawn.

What Kind Of Software Should I Use?

Today’s more recent 3D printers almost come with a software system that is either available for download or is on an operating disk. In the past, 3D printing software had several parts that came in separately. Back then, you would have to coordinate them for the whole thing to function properly manually. It was not an easy install. Fortunately, today, it is now a seamless, user-friendly installation procedure that makes it easy for the beginner or even the pro as the case may be. There are different softwares used for different 3D printers like 3D printers for home, wifi 3D printers and more.

Top-Rated 3D Printers

3D printers are becoming more affordable now more than ever. In the 3D printers library, pick up for the Phrozen Lite 3D Printer has provided stable performance for users. With that in mind, as a buyer, you must first know the features you are looking for because a high price may mean quality but not to your specifications.

3D Printers

Frequently Asked Questions

1. Is buying a 3D printer profitable?

Yes, you can use the 3d printer to build your own designs and you can also run a small business to make money.